Linear Axis Monitoring and Optimization

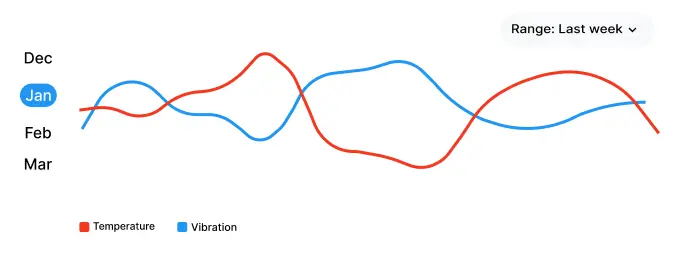

Our software captures real-time data from linear axes, providing precise calculations of speed, positioning, and acceleration. This data can be used to optimize process parameters, identify hardware issues, and improve overall performance. Cloud integration allows for easy comparison across multiple machines, identifying outliers and potential process improvements.